The Pros and Cons of Screen Printing vs. Digital Printing for Your Merch

In an age of limitless customizations, you can create beautiful, unique garments or products that outshine any basic T-shirt you get from a store. And with multiple methods for creating custom products, you can choose the best option to fit your needs. So, how do you choose the right approach for the merchandise of your dreams?

The most popular printing methods are screen printing and digital printing. With technological advancements for each one, you can print gorgeous items regardless of which you choose. But when you take a closer look at screen printing vs. digital printing, they both offer strengths and weaknesses that can affect the final look of your printed products.

Whether you’re creating apparel or gifts for your brand, sports team, or family reunion, you want it to feel personal and high-quality. In the battle of screen printing vs. digital printing, the winner depends on your custom merch goals.

Understanding Screen Printing

The roots of screen printing go back to ancient times, and, surprisingly, the mechanisms haven’t changed much since. The process involves transferring a stenciled design onto your chosen material by forcing ink through a mesh screen in the shape of the design. While originally meticulously performed by hand, newer automated machines can easily screen print sizable loads at a time.

Screen printing is the staple method of many printing operations and allows easy customization. You can create various ink styles with this method, like raised textures, shines, foil, fluorescents, or glitters. After years of evolving to its current form, screen printing has become the go-to method for printing large orders. From sports apparel to corporate swag, screen printing offers vibrancy and versatility when creating your custom merch.

Understanding Digital Printing

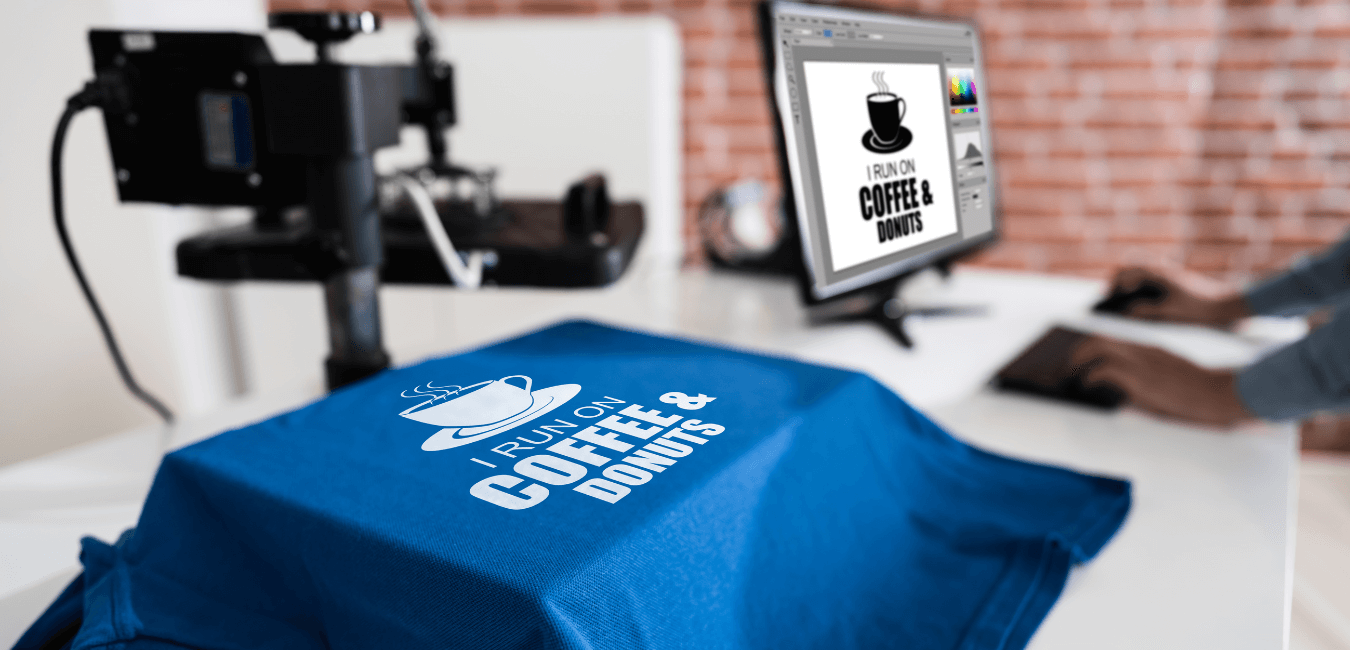

Digital printing or direct-to-garment (DTG), a technique created in the last few decades, works like an inkjet printer by printing the ink directly onto the fabric. The machine then heat seals the ink to the garment, giving you long-lasting wear. Digital printing is best for apparel with complex designs or high levels of detail. Because the layers of ink are thinner, the printing can be more precise.

Digital printing is an easy method that takes your design straight from your computer screen to your product. Once you’ve designed your print file, you can expect consistent printing with equal ink distribution for each piece. Due to the minimal setup required for digital printing, many companies turn to this method for printing smaller batches of apparel or products. Creating merch for a small event or family vacation? Digital printing offers the ease and consistency you need.

Pros and Cons of Screen Printing

There’s a reason screen printing has remained a staple method of the custom apparel world. Its strengths lie in its cost-effectiveness for large orders, durability, and quality on multiple materials. You can screen print on almost any kind of surface, including fabric, wood, leather, glass, or plastic. From custom apparel to reusable water bottles, screen printing wins in versatility.

Screen printing is a crowd favorite for a reason. It’s affordable, the color vibrancy is unmatched, and it’s made to last. It’s the best choice for printing on dark fabrics since the colors print so vividly. Screen printing works well with relatively simple designs. What it lacks in complexity, it makes up for with quality that packs a punch.

While screen printing offers a great payoff, it takes more time and labor to set up. It’s also more expensive, particularly for smaller print quantities, and requires a larger investment upfront. You may be limited in the number of color gradients due to available inks. And if your design includes a lot of tiny details, there’s the potential for colors to bleed into each other.

Pros and Cons of Digital Printing

In an era of instant gratification, digital printing solves your quick printing needs. It requires minimal setup, so it’s the better choice for smaller print orders, frequent design changes, and quick printing.

Digital printing offers a crisp finish best suited for detail work. It’s practically unlimited in what you can design, making it easy to personalize. If your artwork includes intricate color blends with multiple pigments, digital printing works best. It’s consistent with quality – you don’t have to worry about colors bleeding or one garment turning out lower quality than others. It produces a sharp image every time.

Printing merch digitally can have some drawbacks, such as color differences. Pigments may differ from the computer screen to the printed product. Expect digital printing prices to increase for larger orders. You also will likely be more limited in what materials you can print on. Due to the thin layers of the ink, you may experience the colors fading more quickly over time.

Screen Printing vs. Digital Printing

Each method offers benefits, so it is best to choose the one that fits the needs of your artwork. From color payoff to print speed to cost-effectiveness, you may favor one method over the other for your next project.

Vibrancy

Screen printing offers the most vibrant color payoff and color match accuracy. Each ink is mixed for the individual paint job to get the exact colors you’re looking for. Digital printing relies on the colors available through the CMYK color gamut, meaning you won’t have as many hues available at your disposal.

Winner: Screen printing

Color Blending

When it comes to creating smooth color gradients, digital printing comes out on top. High resolution allows ombre, shadows, and diffusions to print seamlessly without bleeding. It’s more difficult to achieve with screen printing, especially when trying to print multiple colors simultaneously.

Winner: Digital printing

Durability

Digital print designs can fade over time and with repeated washing, while screen printing maintains its vibrancy for years to come. While both processes can get the job done, screen printing may be a better choice for items you want to stand the test of time.

Winner: Screen printing

Consistency

From the computer to the final product, digital printed products come out the same every time. If screen tension is too low before screen printing, it can cause edge-blurring, decreasing the quality. It can be consistent, but several variables can affect the quality if not set up properly. In other words, you need to rely on experts like those at Lettering Express to get it right.

Winner: Digital printing

Versatility

Screen printing allows for printing on various textiles, materials, and products. You can also find more specialty ink options that can only be done with screen printing. Some specialty inks can be digitally printed, but they are harder to find.

Winner: Screen printing

Detail Work

For fine lines, tiny details, and small texts, digital printing is the clear winner. It creates sharp, crisp edges that don’t blur. You may need to increase the size of certain elements of your design to effectively screen print your merch.

Winner: Digital printing

Cost-Effectiveness

For large quantities of orders, screen printing works best. Although it has a higher set-up cost, it’s spread out over multiple products if printed in large bunches. For smaller quantities, digital printing makes sense. It’s a low startup cost, allowing you to spend your budget on more colors or details.

Winner: Depends on the project

Speed

Due to its minimal setup, digital printing produces smaller quantities faster. However, it is limited in how many it can print at a time. Screen printing takes longer to set up but can print larger orders at a time, making it the better option for high quantities of products needed.

Winner: Depends on the project

The Verdict

Screen printing wins in vibrancy, durability, and versatility in printing options. When it comes to intricate details like fine lines, skin tones, and complex fonts, digital printing offers accuracy, color blending, and consistency.

Create Something Special

The world of custom printing offers powerful options for creating unique products. While both screen printing and digital printing present various benefits, your project needs will determine the method you choose. For color payoff, versatility, and endurance, screen printing is the best option. Digital printing offers high precision and quick turnaround times and works best for small batches. Each method can help you create unique, high-quality products. Think about your custom merch goals to determine the best fit for you.

At Lettering Express, we know the power and potential that screen printing and digital printing offer. With more than 35 years in the industry, we’ve got the expertise to help you find the best method for your custom printing needs. Give us a call today to discuss how we can create the high-quality custom merch you’ve been looking for.